|

Moldings / Selfedge

HOW TO APPLY MOLDINGS AND "SELFEDGING"

MOLDINGS

-

Apply glue to molding.

-

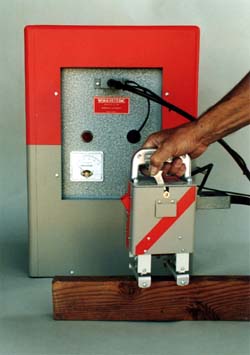

Place

molding on edge to be glued and place electrode feet across the molding.

-

Apply

ample pressure with hand unit.

-

Pull

trigger switch and tune lever. Hold

pressure until glue stops boiling.

-

Sand

and finish.

NOTE: The

electrode feet are usually in the small gap position when doing narrow moldings.

SELF-EDGING (Plastic and Wood)

-

Apply

glue evenly to both surfaces.

-

In

most cases, the glue application should be a little heavier as it soaks into the

end grain.

-

Press

the electrode feet, in the small gap position, across the edging strip

and apply pressure. Start at one

end and slide or walk the hand unit along the edge keeping an even, flat

pressure.

-

If

a self-edging strip is to be added after the plastic top is on, then a piece of

masking tape must be put along the top edge to insure ease of removing any

excess glue that may boil out and over the finished top.

-

Edge

is ready to be finished.

-

Maximum

cure will result in about 24 hours.

NOTE:

We feel the best method of applying edging is to place a piece of quarter

ply or Plexiglas on top, then use the roller electrode feet as described.

|

|